Design for Disassembly Shoe

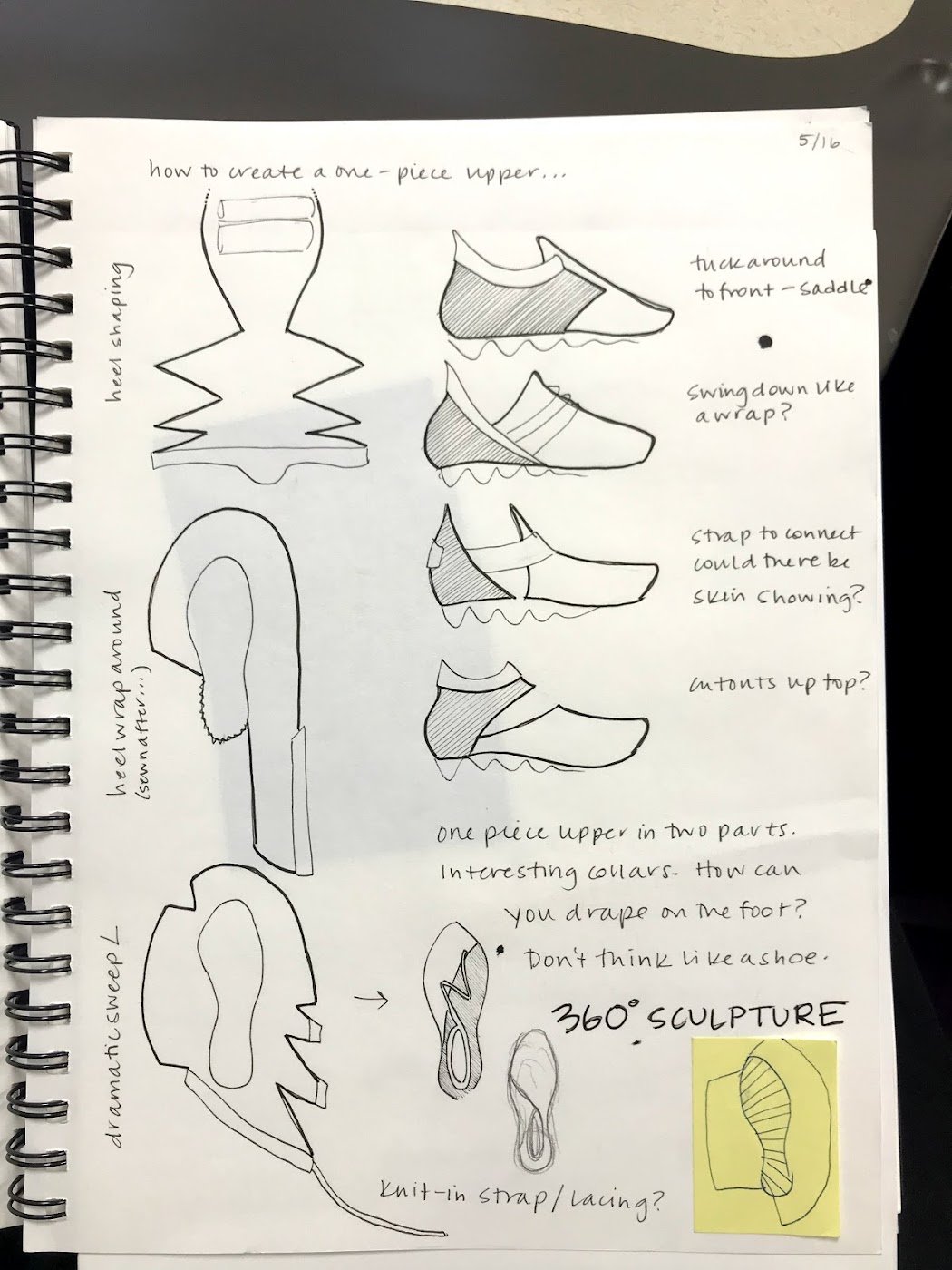

What might a one-piece sustainable lifestyle shoe made without stitched components or glue look like? I explored this prompt early in my time at New Balance as a personal project. I created a foldable origami-style upper that comes off the Stoll machine in one fully-fashioned piece. The wrap-around upper is attached to knitted-in tubes along the sole of the shoe that allow for customizable foam inserts to provide personalized support and comfort. Most shoes are constructed as a “monstrous hybrid” with numerous parts glued and stitched together that cannot be easily separated and recycled or replaced as they wear out. Additionally, I’ve spent a lot of time on the New Balance factory floor watching how many hands touch a pair of shoes before it is complete; traditional shoe construction requires significant labor and post-processing that increases time, cost, and human effort. I wanted to create an inspirational knit project that explored sustainable footwear solutions that reduced the number of components, adhesives, and labor involved.

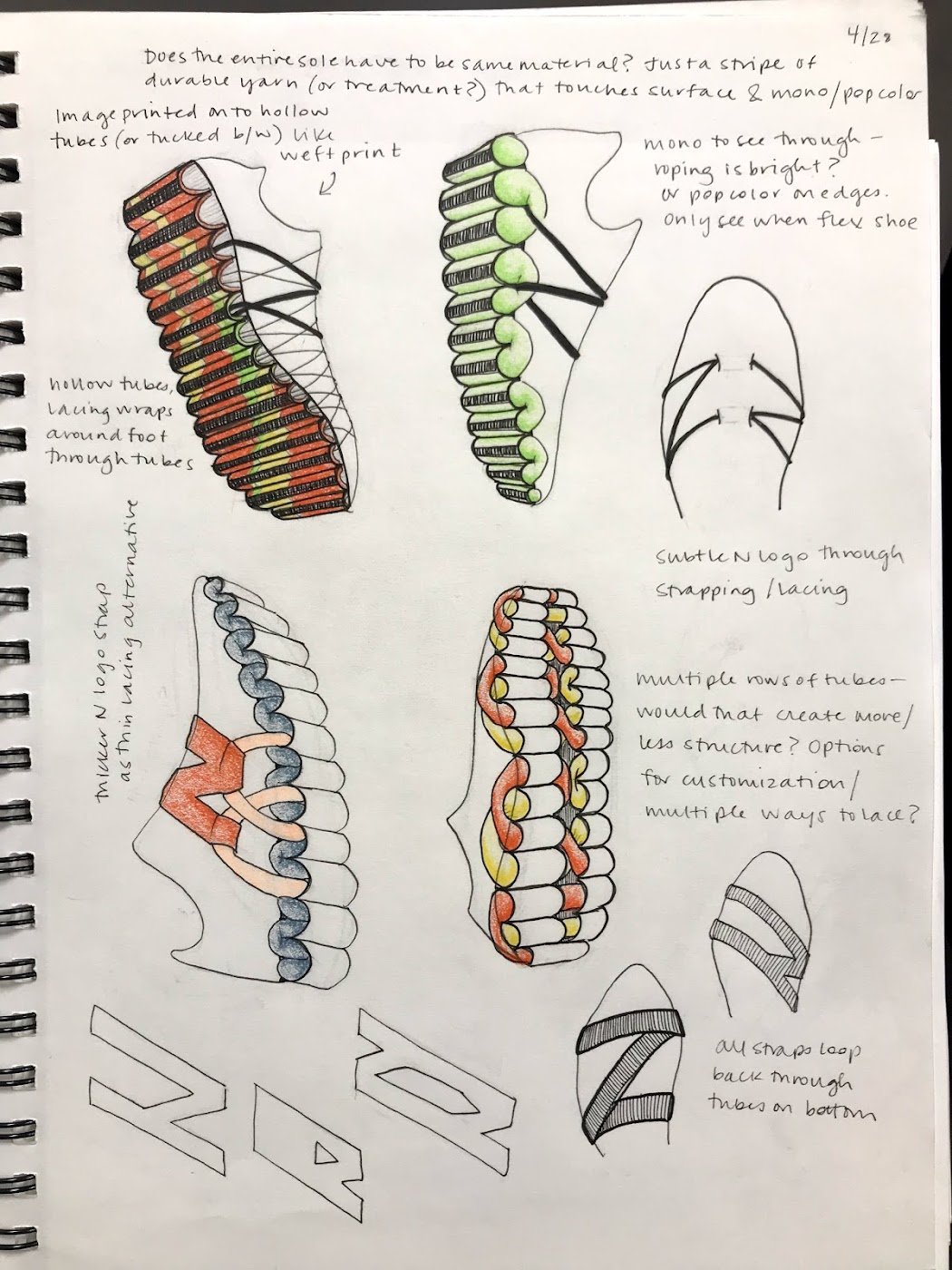

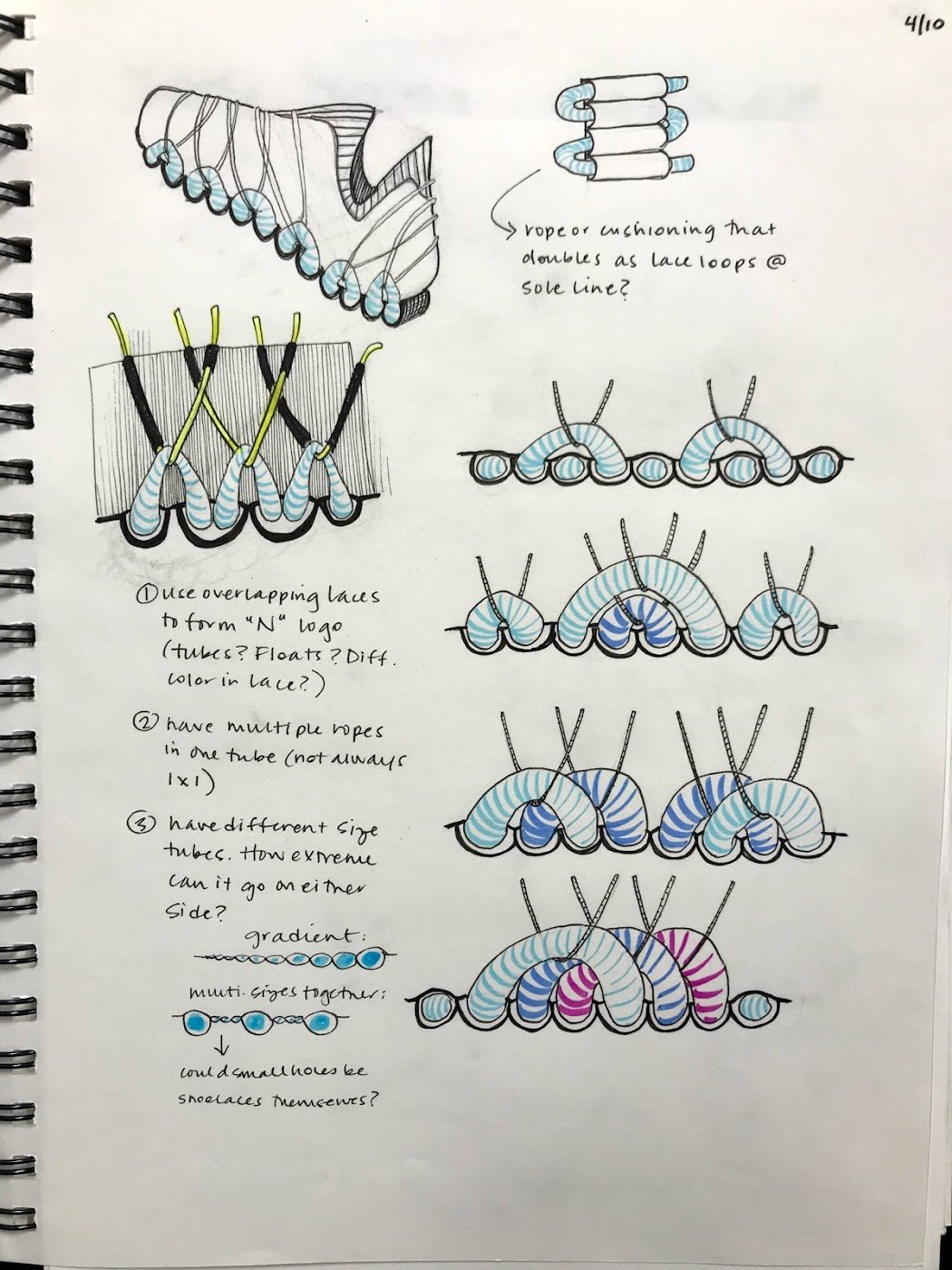

The following swatches were created to explore connection and form

Dimensional shaping exercises to create a 3D fully fashioned upper that fit the last

Notes, sketches, and 3D mockups